|

|

|

Model |

Wafer |

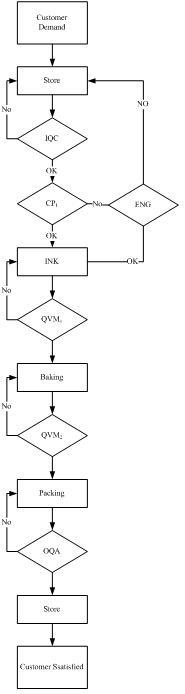

CP Flow Control Chart |

|

Dept. |

QRA |

|

Symbol |

□: Operation ◇:Inspection↑↓:Move |

|

Item |

Process Flow |

Process |

Control Point |

|

1 |

|

Supplier |

Quantity check |

|

2 |

Store |

1. Quantity check |

|

2. type No. check |

|

3. Batch No. check |

|

3 |

Incoming Inspection |

1. Quantity check |

|

2. type No. check |

|

3. Spec verify |

|

4 |

CP Elec. Functional Test |

1. Elec. Spec. verify |

|

2. Program check |

|

3. Yield control |

|

|

|

|

5 |

INK |

1. Ink viscosity check |

|

2. Ink mark spec. verify |

|

6 |

QC Visual Inspection |

1. Ink mark spec. verify |

|

2. Appearance |

|

7 |

Baking |

1. Pre-heating 20 min. |

|

2. Heating 30 min. Keep 125*C |

|

3. Reduce heating 30 min. |

|

8 |

QC Visual Inspection |

1. Ink mark spec. verify. |

|

2. CP spec. verify |

|

9 |

Packing |

1. Quantity/ type/label check |

|

2. Lot No. /appearance check |

|

10 |

OQA Visual Inspection |

1. Quantity/ type/label check2. Lot No./appearance check |

|

11 |

Store |

1. Quantity/ type/label check |

|

2. Lot No. /appearance/P.O. check |

|

|

|

|

12 |

Supplier |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|